Description

Data

Features

Downloads

Certificates

Description

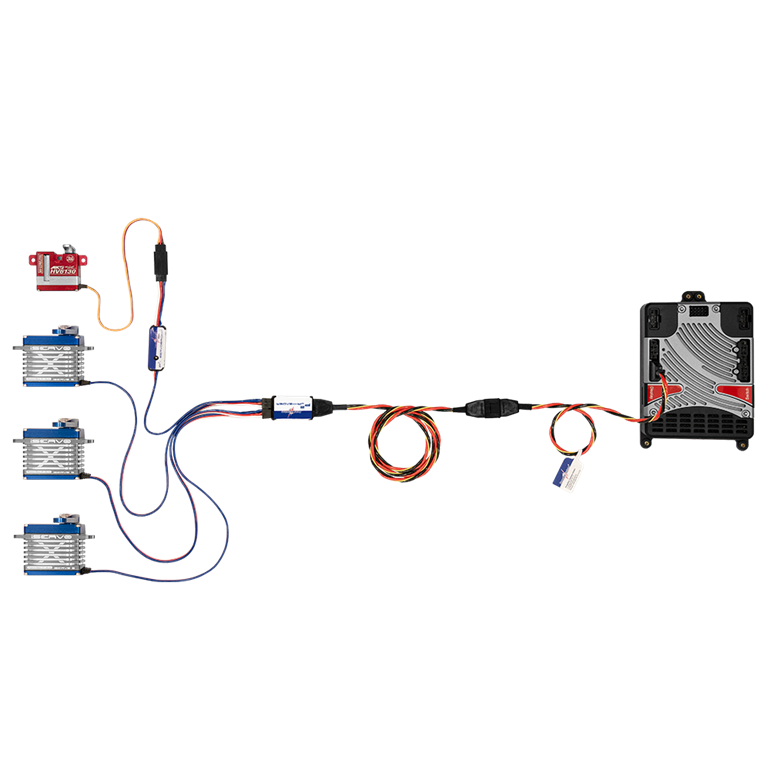

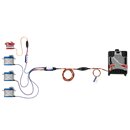

The P²-ServoBridge is the key component in an entirely new servo bus technology which presents unprecedented possibilities. If a servo bus is employed, only one cable is required for several servos. The servos are individually addressed, and therefore each servo knows which signal is intended for it. Earlier servo bus systems simplified the wiring in the model; for example, saving multiple plug / socket connections in the wings. The new feature of the PowerBox P²-Bus is that it works bi-directionally! This means: not only can accurate digital signals be fed to the servos, but important telemetry data - such as current, voltage, temperature and other information - can also be fed back to the CORE or ATOM transmitter.

Targeted alarm settings at the transmitter alert the user to defects in good time, so they can be corrected without the need to analyse reams of data. But even that's not all: the parameters of the P²-ServoBridge can be altered directly from the transmitter. The integral electronic fuse can be adjusted to suit the particular servo, precisely to the milli-second and milli-amp. A micro-controller decodes the bus signal, monitors the current accurately and at high speed at the servo itself, and switches the servo off reliably if the set thresholds are exceeded.

This technology eliminates all the disadvantages inherent in simple resettable fuses (polyfuses) - such as temperature dependence or ageing effects. A range of pre-set profiles enables any modeller to find the correct setting for a particular servo even without a knowledge of electronics.

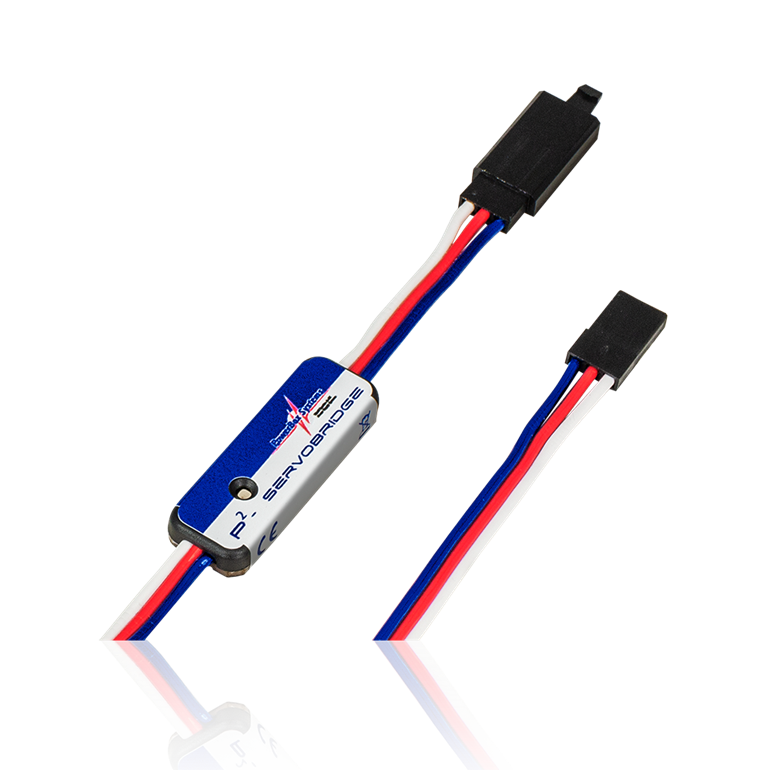

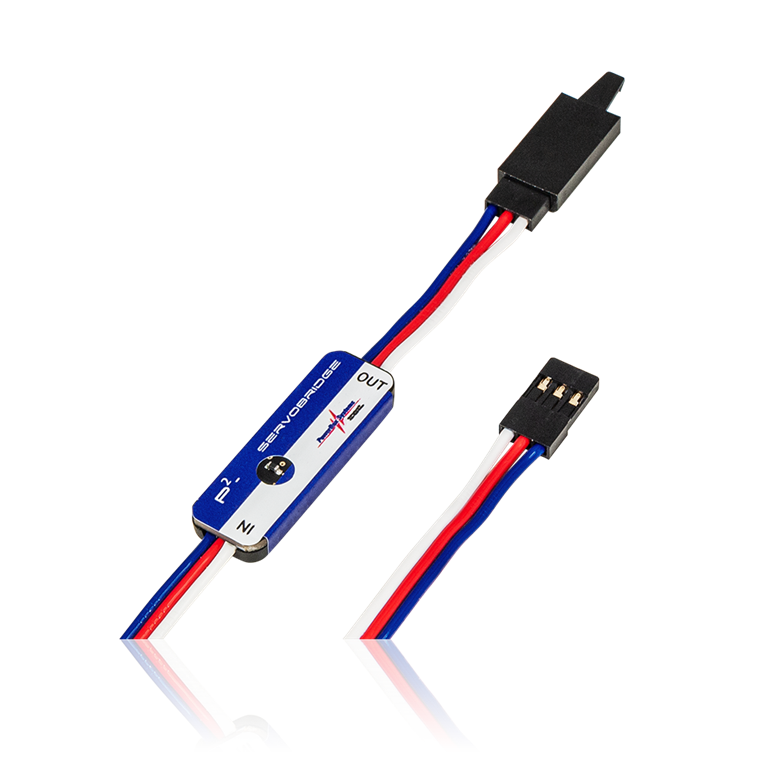

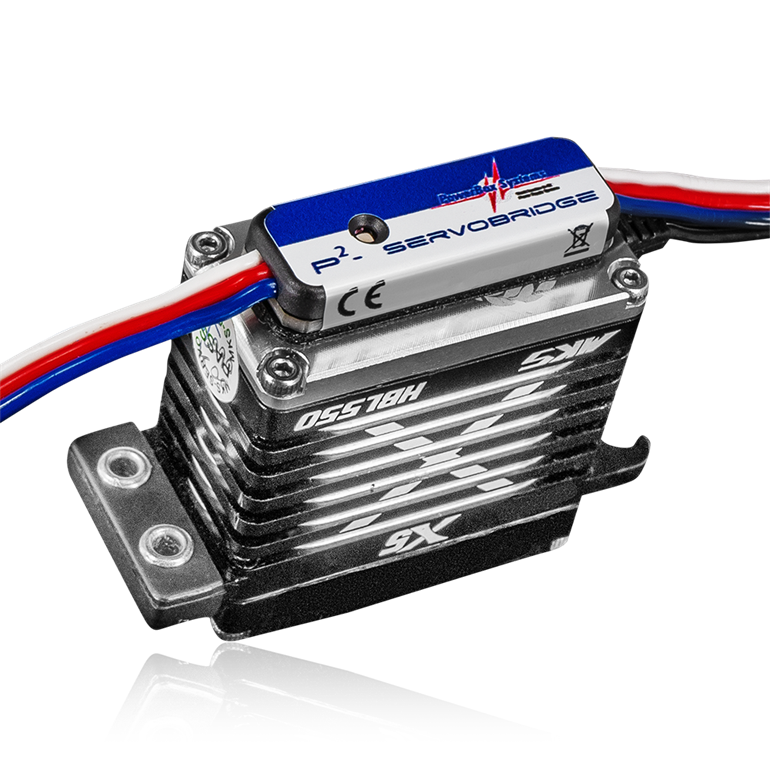

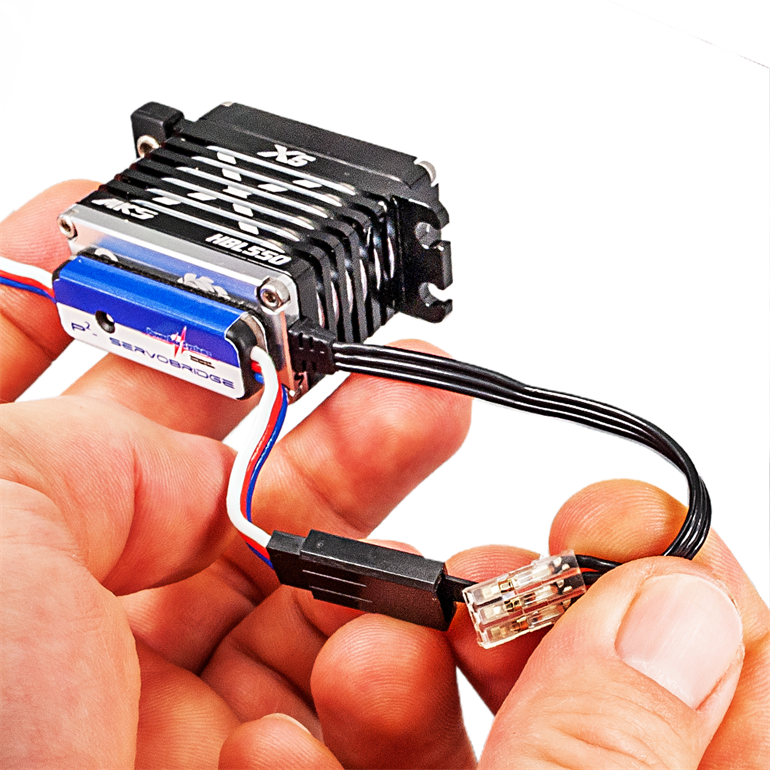

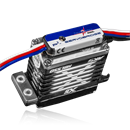

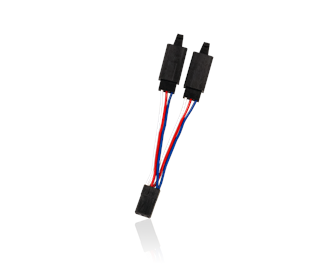

The adhesive pad supplied is used to attach the P²-ServoBridge to the bottom or side of the servo case, where it also monitors the servo temperature. In addition to the P²-BUS, the P²-ServoBridge works with other bus systems such as S.BUS or SRXL, and even with conventional PWM servo signals. This means that the device can also be used for accurate over-voltage power-off - for example, with retract servos - even when bus wiring is not used. The input signal is detected automatically, and the fuse is pre-set to suit standard servos with an output torque of up to 30kg/cm, so in most applications the P²-ServoBridge can be used as a Plug ´n Play device.

Data

| Operating voltage | 4.0V - 10.0V |

| Current drain Power-on state | 10mA |

| Maximum load current | 20A |

| Signal input | P²-BUS, S.BUS2, EX-BUS, SRXL, PWM |

| Supported RC systems | PowerBox, Jeti, Futaba, all with PWM |

| Supported telemetry systems | P²-BUS, S.BUS2, EX-BUS |

| Channels | 26 |

| Servo sockets | 1 |

| Servo signal resolution | 0.5µs |

| Dimensions | 35 x 12 x 5 mm |

| Weight | 4 g |

| Temperature range | -30 °C bis +85 °C |

Features

+ Automatic detection of the bus system in use

+ Can be used with P²-BUS, S.BUS2, SRXL/UDI or PWM

+ Telemetry data for PowerBox, Jeti and Futaba radio control systems

+ Current, voltage and temperature acquired at the servo itself

+ Adjustable at the transmitter with PowerBox and Jeti radio control systems

+ Unrestricted choice of bus channel

+ Variable PWM frame rate: 12ms, 14ms, 16ms and 18ms

+ Accurately adjustable electronic fuse

+ Automatic fuse reset function

+ Facility to set two separate cut-off currents and times